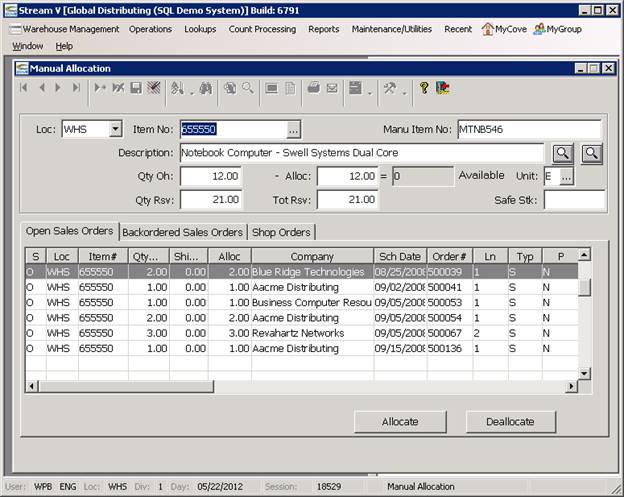

Manual Allocation

The Manual Allocation program allows you to control how the available on hand inventory quantity for each item is distributed to the open sales order and shop order lines for the item. The manual allocation program allows you to over-ride the automatic inventory allocation that is performed by the system, and to select the orders that the available inventory for the item is allocated to.

Manual Allocation is used to handle the following situations.

Re-assigning inventory that is allocated to sales or shop order lines for each item to allow selected orders to ship

Allocating inventory that is not set to allocate automatically

Allocating safety stock quantities.

Manual Allocation allows you to handle the following types of items.

Warehouse shipment sales order lines

Kit items and kit components

Special order sales order lines

The Manual Allocation program displays all of the open and backordered sales order lines and any open shop order lines for the selected item. Both Sales Order (type S) and Loaner (type L) sales orders are displayed by the program.

Once a valid item has been selected in the Manual Allocation program, you may use the program to

• Manually allocate any available inventory quantity to the sales or shop order lines displayed in the program. This option allows you to manually allocate items that are not processed by the automatic allocation process that runs at the end of the receiving. This option can also be used to allocate the safety stock quantity for the item if a safety stock quantity has been defined for the item (the system does not automatically allocate any safety stock quantity that is defined for an item).

• Manually de-allocate a portion or all of the allocated quantity for a specific shop or sales order line so that it can be allocated to another shop or sales order line. This option is used when you need to manually specify which orders should receive allocation - or over-ride the automatic allocation that was performed by the system. This option is normally used when you do not have enough stock to fill all current orders for the item.

Please note:

• Your ability to access the Manual Allocation program, and your ability to use the program to allocate and de-allocate inventory can be restricted using system parameters. If you are unable to perform a specific function in the program you should verify the parameters used by the program have been set correctly by your System Administrator.

• You may not allocate to or de-allocate from sales order or shop order lines that are flagged as printed (in this case, a sales order pick ticket or shop order pull ticket is being processed for the line, and the system will not allow you to change the allocated quantity as it was printed on the document). If you need to allocate to or de-allocate from a printed sales order or shop order line item, you should first re-set the appropriate document and then modify the allocated quantity.

• You may not manually allocate or de-allocate non-stocking items. Non-stocking items are assumed to be always available by the system and these items will always be fully allocated if they are included in a shop or sales order.

• You may not manually allocate to or de-allocate from a vendor shipment sales order line. Vendor shipment lines are tied to specific purchase orders, and these lines are shipped directly by the vendor (they do not come out of any of your warehouses).

More:

Prompt Button - Inventory Detail Panel

Prompt Button - Inventory Detail Panel

Prompt Button - Catalog Detail Panel

Prompt Button - Catalog Detail Panel