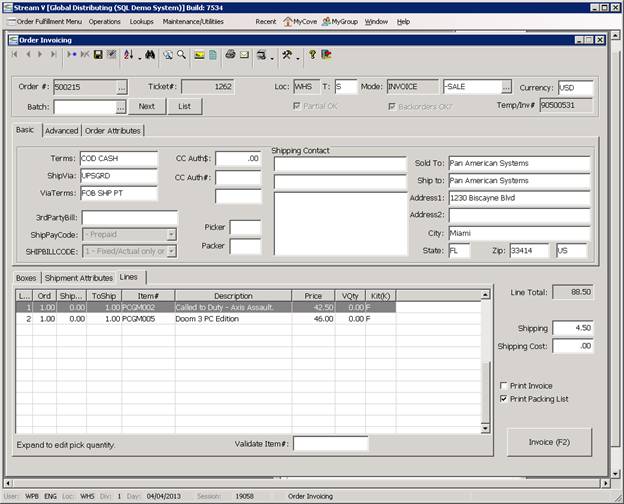

Order Invoicing

The Order Invoicing Program is used to invoice or complete sales and loaner orders that are being fulfilled from your warehouse locations.

The Order Invoicing program is used to confirm the items and quantities being shipped out or processed, to enter serialized inventory and shipment information into the system, and to create invoices, credit memos, and shipper invoice documents.

Order Invoicing is called from several different applications in the system.

• Menu - The Order Invoicing program can be selected from the Order Fulfillment Menu and used to invoice sales order and loaner orders that are being completed from your warehouse locations. The Order Invoicing Menu is normally located on the Order Fulfillment/Operations Menu, but it can also be included on MyCove and MyGroup Menus.

• Vendor Shipment Processing - The Order Invoicing program is called from the Prepare to Invoice Vendor Shipment program when a vendor shipment is invoiced in that program.

• Accounts Receivable - Order Invoicing is called from the AR Lookup program when the Credit Invoice option is selected in that program. When the Credit Invoice option is used, the system automatically loads the lines from the selected invoice into the program, and it changes the items quantities from positive to negative. The operator may edit the credit memo information as required (delete lines, change quantity being returned, adjust the serial detail, etc). When the credit memo is saved, the items are returned to stock and a credit invoice is created for the customer.

• Pending Management - The Order Invoicing program is activated from the Pending Management program when the Invoice Customer option is used in that program. The Invoice Customer option allows you to create a sales or billing invoice for items that have already been delivered to the customer using a Loaner shipment. The Pending records for the items being invoiced are closed out based on the quantity being processed, and a normal invoice is created for the customer.

When the Order Invoicing program is called directly from the Menu, a “Picklist” is required in order to create an invoice or shipper (a loaner type invoice). Picklists are documents that are produced in the warehouse. Picklists are printed for the open sales orders (and loaner orders), that are not on hold for any reason, that have goods allocated to them, and that are scheduled for shipment. A Picklist is produced for each order to be shipped out, and this picklist is used to identify the order lines, items, quantities and bins being processed,. The Picklist is used to pull the items to be shipped from the appropriate warehouse bins, and it is also used to create an invoice for the items being shipped out against each order.

The following link can be used to view more information about the Order Invoicing Process.

The Order Invoicing program can also be called directly by other applications in the system as required. Order Invoicing is used by these applications when they need to generate an invoice or credit memo.

When the Order Invoicing program is called from another application (vs the menu), a Picklist is not normally required as goods are not being shipped out by you. The items are either being received in, or the program is being used to invoice items already shipped out . When the Order Invoicing program is called by the Pending Management program it is used to invoice a customer for goods which have already been shipped out to them on a loaner or shipper document. When the program is called from the RA (Return Authorization) Management Program or the AR Lookup program, the program is used to create credit memos for items that have already been returned by your customers. When the Order Invoicing program is used to complete a vendor shipment, the items being invoiced have already been delivered by your vendor.

The Primary Tasks that are performed using the Order Invoicing program are as follows.

• Creating Invoice and Shipper documents. Order Invoicing creates shipment documents for the shipments that are completed or sent out from your warehouse locations. The Order Invoicing program allows you to process partial or complete shipments against each sales order line being invoiced, and it also allows you to optionally add nonstock inventory items to an order while it is being invoiced. Nonstock Inventory items can be used to add charges such as labor or expedited shipping to an invoice “on-the-fly” during the invoicing process.

• Entering Serial Information. Identifying and validating the serial numbers of any serialized inventory items being shipped out. The Order Completion program ensures that valid serial numbers are input for each serialized item being shipped out and it forces the number of valid serial numbers entered for each serialized item to match the quantity being shipped for each item.

• Entering Shipment Information. Recording the shipping or manifest information associated with each shipment. The StreamV Order Fulfillment system can be used to automatically manifest any shipments that are being shipped using a supported automated shipping method such as UPS, FEDEX, or Airborne.

• Creating Invoices from other applications in the system. The Order Invoicing program is used by other systems to create invoices and credit memo documents. When the program is called by other applications (instead of from the menu), the program does not require the operator to load a picklist in order to create an invoice, as the calling application loads the appropriate information into the program, and no goods are being shipped out.

The following sections describe the various components in the Order Invoicing program and how they are used. For more information about creating invoice documents for warehouse shipments with the program, please see the Daily Procedures section of this document. For more information about how the program is used by other applications in the system, please refer to the documentation for the application.

More:

Order Number Ticket Number Panel

Order Number Ticket Number Panel